MEP Coordination Drawings: Conflict Resolution and More

We’ve come a long way from when construction coordination was simply avoiding on-site physical conflicts with equipment layout and piping or ductwork routing. Today, coordination drawings make it easy to identify potential conflicts in the placement of electrical, mechanical, and/or plumbing systems before construction begins.

What are Coordination Drawings?

MEP (mechanical, electrical, plumbing) coordination drawings are used in commercial construction projects to reduce clashes between the different trades. Along with confirming there’s adequate space for all intended equipment, they can reduce, if not eliminate, changes that typically arise from:

Redesigning MEP systems in the field.

Having to open ceilings or closed walls to install, relocate, or connect electrical and mechanical systems.

The trades of MEP Coordination include:

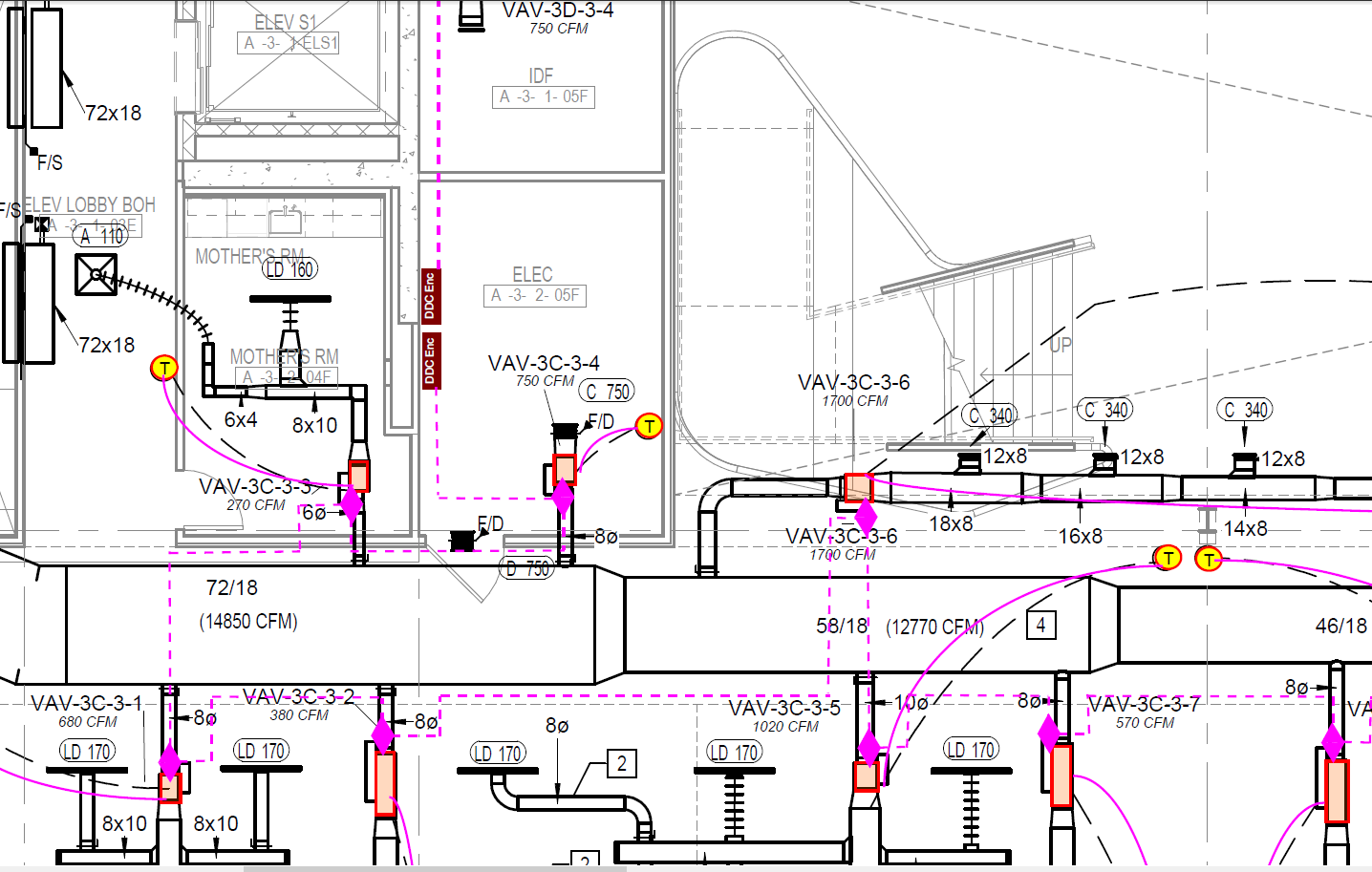

Mechanical systems such as HVAC equipment, cooling towers, and ductwork.

Electrical systems including panels, elevators, switchboards, cable trays, transformers, and more.

Plumbing systems like water holding tanks, sewage pits, pumps, and grease and sand traps.

Other systems include fire safety and external components including rooftops and facades.

For any building manager, engineering firm, or general contractor whose motto is “first time right,” coordination drawings are the solution for preventing costly construction overruns.

The Importance of Coordination Drawings

Critical to the success of any modern commercial building project, coordination drawings show horizontal and vertical dimensions to avoid individual system interference with structural framing, ceilings, partitions, lighting, and other services. HVAC ductwork routing, plumbing or process pipes, and instrumentation cable trays are all coordinated between each other. Each contractor can then effectively construct the project with minimal time lost waiting on input from other contractors.

This coordination process facilitates fabrication and installation of building systems to industry best standards and results in improved work quality, faster design time, and greater productivity.

Benefits of Coordinated Drawings

Less coordination time, simultaneous design, and improved document quality lead to lower costs and less miscommunication. Other benefits include:

Improved collaboration and visualization. Space is optimized through a two-step process. Primary MEP and other components are placed first and then secondary components are placed around these core elements.

Harmonious projects enabled by buildings plans and MEP layouts being designed at the same time.

South Florida Controls uses a coordination process that results in an installation plan that’s objectively best for the construction project as a whole. Together with other solutions like prefabrication and cloud engineering, coordination drawings save you time and money by reducing construction costs. For building owners and managers and construction managers looking to improve their bottom line through state-of-the-art technologies, coordination drawings offer all that and more.